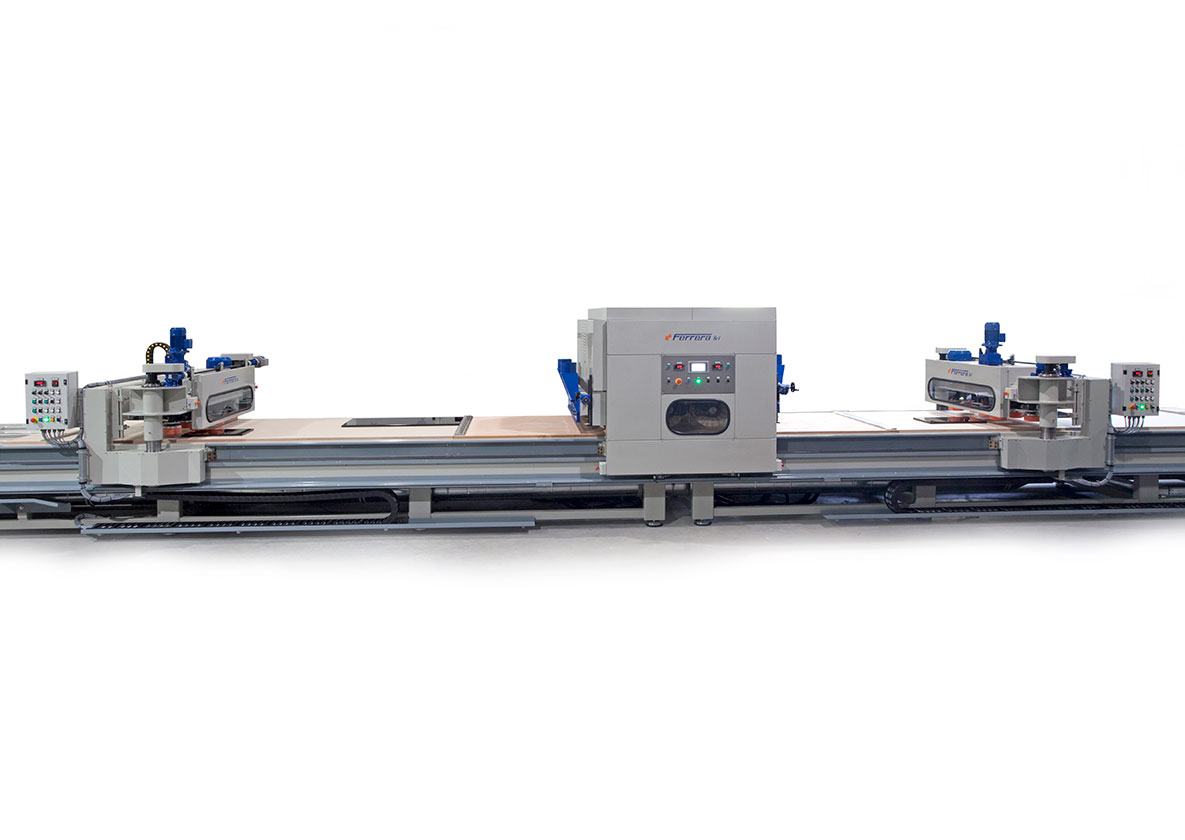

TWO STATION CONTINUOUS PRODUCTION LINE FOR POLISHING WITH DEPRESSOR

This machine represents an ideal solution for the polishing of polyester varnishes, poliuretanic and granites.

PARAMETERS

Thanks to our many years of experience we have created this tested machine.

Thanks to its double stations (one for loading and the other one for unloading) its maximum potential is reached, eliminating downtime.

N. 2 roller brushing machines:

- Rollers Ø 350 x 1300 mm tilted and swinging

- Main engines: 2 x 11kw at variable speed with inverter

- Fixed double station 8 (one for loading and the other for unloading)

- Panel blockage through negative pressure and frontal mechanical blockages

- Depressor power: 2 x 9.2 kw

- Control panel on board to regulate parameters

Control panel on board for parameters regulation

Adjustment of work parameters is simplified thanks to the touch screen control panel.

N. 2 Sliding Buffing Machine With 9 Buds

- Rotating swinging foam buds of Ø 160 mm attached to two axes (3 groups of buds)

- Main engine is 5.5 kw with variable speed and inverter

- Toothed belts fixed transmission are exempt from maintenance

- Control panel on board

Thanks to the independent movement of the buffers, the maximum potential of the machine is reached, eliminating downtime.

This innovative machinery makes sure that the final result is even well polished and shiny.

TWO STATION CONTINUOUS PRODUCTION LINE FOR POLISHING WITH DEPRESSOR

This machine represents an ideal solution for the polishing of polyester varnishes, poliuretanic and granites.

PARAMETERS

Thanks to our many years of experience we have created this tested machine.

Thanks to its double stations (one for loading and the other one for unloading) its maximum potential is reached, eliminating downtime.

N. 2 roller brushing machines:

- Rollers Ø 350 x 1300 mm tilted and swinging

- Main engines: 2 x 11kw at variable speed with inverter

- Fixed double station 8 (one for loading and the other for unloading)

- Panel blockage through negative pressure and frontal mechanical blockages

- Depressor power: 2 x 9.2 kw

- Control panel on board to regulate parameters

Control panel on board for parameters regulation

Adjustment of work parameters is simplified thanks to the touch screen control panel.

N. 2 Sliding Buffing Machine With 9 Buds

- Rotating swinging foam buds of Ø 160 mm attached to two axes (3 groups of buds)

- Main engine is 5.5 kw with variable speed and inverter

- Toothed belts fixed transmission are exempt from maintenance

- Control panel on board

Thanks to the independent movement of the buffers, the maximum potential of the machine is reached, eliminating downtime.

This innovative machinery makes sure that the final result is even well polished and shiny.